How To Deodorize Your factory |Rubber Industry|Rubber tire manufacturing factory ventilation|

At a tire manufacturing factory where natural rubber is processed, a very unpleasant odor hangs in the vicinity. Although activated charcoal deodorant equipment and combustion deodorant equipment are effective against rubber odors, in general, its ventilation air capacity is high and a large initial running cost is required.

Answer

First of all, we checked the status of the odor emitted from the factory.

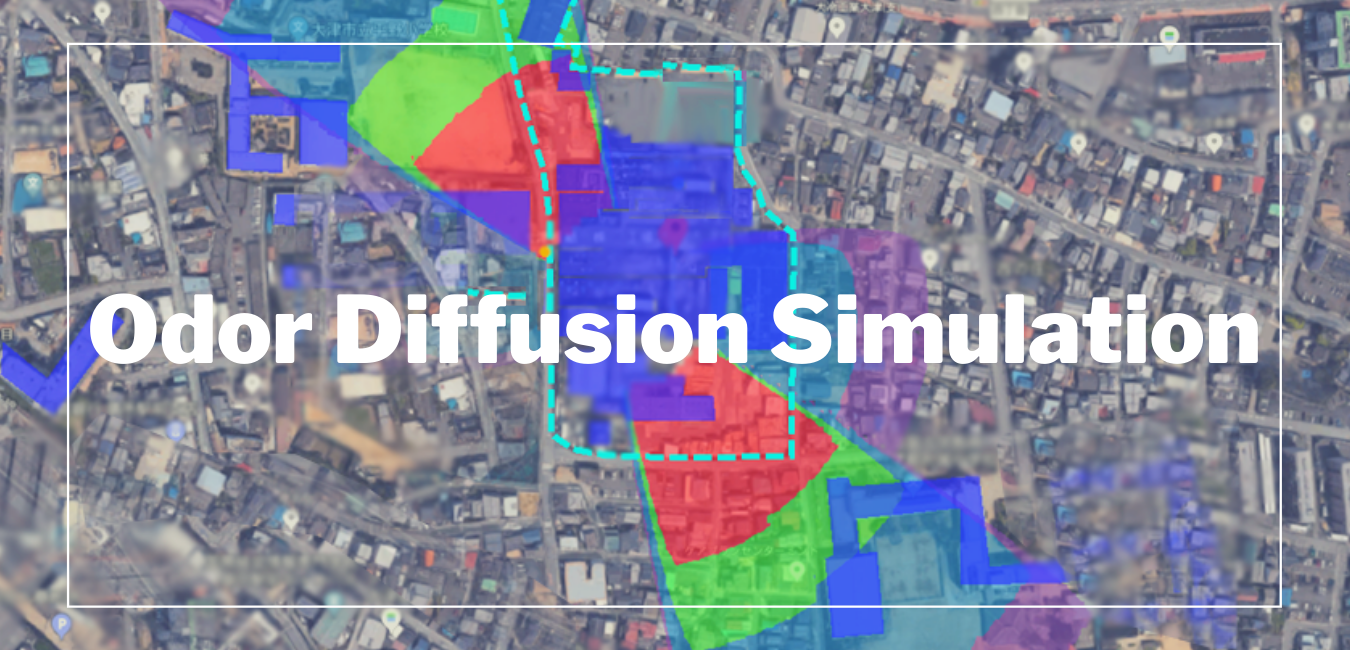

Implementation of odor concentration measurement. And then we investigated measures with consideration for diffusion into the area generating complaints, etc.

We place great importance on checking the spread of odors. Therefore, the odor is sampled, the odor concentration is measured, and the measured odor concentration and air volume data are input to the diffusion simulation software, and the odor diffusion status is confirmed on the simulation.

As a result we first implemented the airflow measures in the factory.

We outfitted the airflow combined with heat and dust measures to improve the conditions where the odor was hard to fill the site.

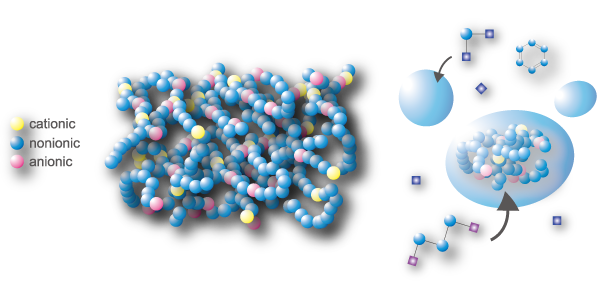

After that Microgel deodorant was sprayed inside the ventilation ducts to greatly reduce the impact of the odor that was emitted from the factory.

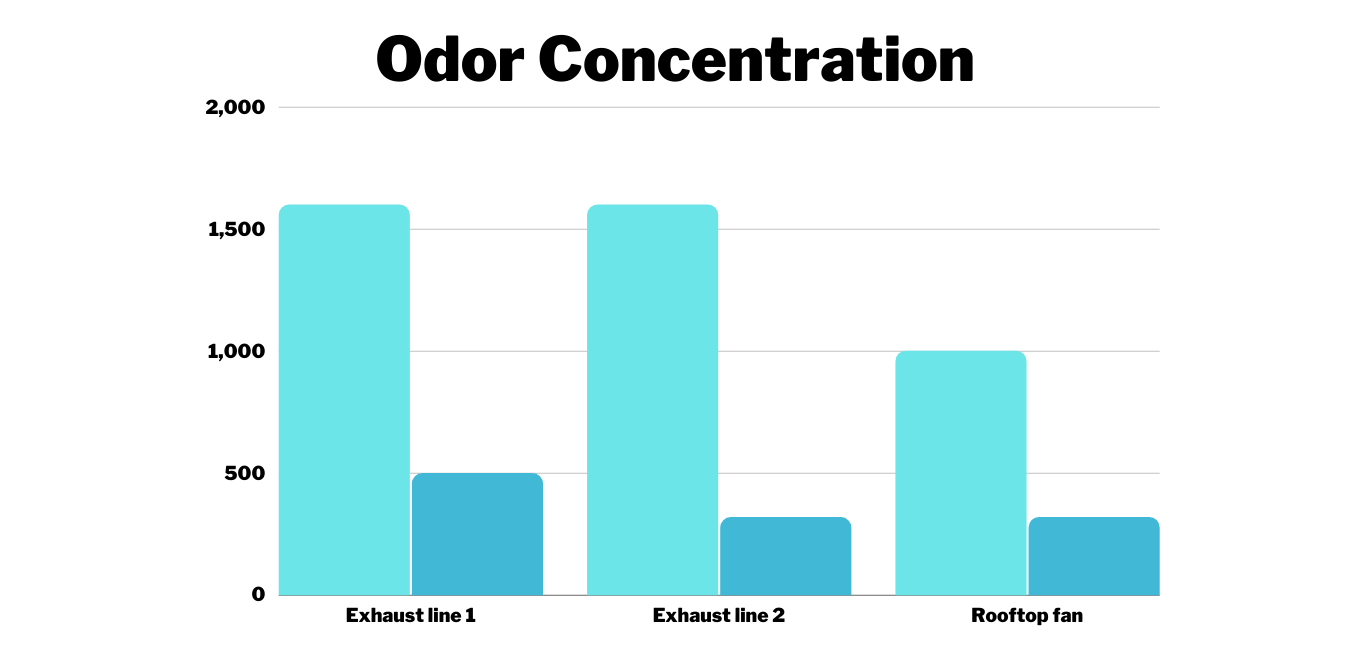

With a spray system, by expanding the nozzles on even one unit it is possible to perform measures for multiple lines,so the initial cost was kept even lower than installing other deodorant equipment. An odor diffusion simulation was performed before introducing the microgel deodorizer. As a result, it was found that the complaints from the local residents could be settled by obtaining 70% deodorization efficiency at this factory.

Analysis

Microgel deodorant has obtained 70% deodorizing efficiency for each exhaust line in the rubber tire manufacturing process.

It is possible to adjust the deodorizing efficiency by adjusting the spray amount and dilution ratio of the microgel deodorant in order to obtain the optimum running cost.

The production of rubber tyres consists of several processes that generate odours.

Providing the best microgel deodorant

In the rubber tire manufacturing process, the vulcanization process is the most common cause of odor problems.

Generally, the vulcanization process emits sulfur compound-based odorous gases.

Sulfur compound-based odors are originally odor components that the human sense of smell easily reacts to, so these odors can easily lead to complaints from local residents.

We develop and sell MICROGEL deodorants that match the polarity of sulfur compound odors.

Lastly

The vision of the Overseas Market Development Department is to regain the normal life of all humankind. The richer the economy, the more factory-made products around us. The factory emits odors in the process of making products. Some of the odors are good and some are bad. Most of the time, it’s a bad smell.

Currently, Japan is said to be an economically prosperous country. The reason why we are able to maintain affluence is that we have people manufacture things around us in other countries where the manufacturing cost is low.

The odor that comes out in the process of manufacturing things is the same in countries with low manufacturing costs. In the process of manufacturing the products around us, we can imagine the faces of people from other countries who suffer from stench. I feel a little guilty about those people.

We would be happy if we could use our 30 years of know-how to make the faces of people who are troubled by the stench smile and return to life when there was no odor.

|

Tomoya Ohmichi(Olfactory Measurement Operator) |

|

Feel free to email me! oomichi.t@karumoa.co.jp |

|

| In addition to odor-related work, I am also developing a Road Bike product business! I love Road Bike. |

空気環境のことで

悩んでいませんか?

カルモアでは、誰もがどこでも安心・快適な空気を吸えるよう、調査から対策まで、

問題解決のお手伝いをしております。些細なことでもまずはお気軽にご相談ください。